Need any help or advice?+44 (0)1782 454499

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

PATTERN MAKING MATERIALS

INFUSION EQUIPMENT & CONSUMABLES

REINFORCEMENTS

MATERIALS & CONSUMABLES

MOULD MAKING MATERIALS

CUSTOMER GALLERY

Carbon Fibre Shoe Horn

With his prior composite experience, Patric wanted to make a stronger shoe horn after the family's plastic one kept breaking. So he chose to use his experience to make it out of carbon fibre.

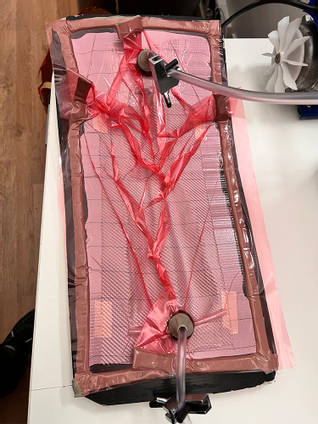

The first step was to use an original shoe horn as a pattern to make the mould from. Once the flanges had been fitted around the shoe horn and the gaps filled with filleting wax, it was time to make the mould. The Uni-Mould Tooling System was used to lay up the mould itself. Once demoulded and trimmed, the mould was ready to make the carbon shoe horn.

To make the part, resin infusion was chosen as the method of choice. Being a smallish part, the lay up of carbon fibre, subsequent vacuum bagging and the infusion itself was relatively simple and quick to do. Once cured, the shoe horn could be demoulded, trimmed and fettled, then put into use. Probably the most high end shoe horn you could ever use!

ABOUT Z06PATRIC

Patric Hagemeister from Sweden. I like working with carbon fibre because I make new carbon fibre parts for my corvette. The first project was a widebody kit for the Corvette. Much of what I have learned has been through Easy Composites' Youtube channel.

CONTACT INFORMATION

| www.facebook.com/Dirtvetten |

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

PATTERN MAKING MATERIALS

INFUSION EQUIPMENT & CONSUMABLES

REINFORCEMENTS

MATERIALS & CONSUMABLES

MOULD MAKING MATERIALS

ABOUT Z06PATRIC

Patric Hagemeister from Sweden. I like working with carbon fibre because I make new carbon fibre parts for my corvette. The first project was a widebody kit for the Corvette. Much of what I have learned has been through Easy Composites' Youtube channel.

CONTACT INFORMATION

| www.facebook.com/Dirtvetten |

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.