Need any help or advice?+44 (0)1782 454499

Specification

Fabric Specification

| Fibre Specifics | High Strength CF | |

|---|---|---|

| Colour | Black | |

| Fibre Orientation | Unidirectional | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | Unidirectional | |

| Format | Unidirectional | |

| Fibre Type | Carbon Fibre | |

| Brand | XPREG | |

| Filament Count | 24K/50K |

Weight and Dimensions

| Width | 300 | mm |

|---|---|---|

| Consolidated Thickness | 0.3 | mm |

| Areal Weight | 300 | g/m² |

| Resin Weight | 33 | % |

Fibre Properties

| Min Cure Temp | 80 | °C |

|---|---|---|

| Max Cure Temp | 120 | °C |

| Max Service Temp | 130 | °C |

| Filament Diameter | 7 | µm |

| Out-life (at 20°C) | 30 | Days |

| Freezer-life (at -18°C) | 12 | Months |

| UV Resistance | Good |

Typical Laminate Properties

| Tensile Modulus | 55.2 | GPa |

|---|---|---|

| Tensile Strength | 645 | MPa |

| Compressive Strength | 615 | MPa |

| Flexural Strength | 882 | MPa |

| Flexural Modulus | 60.1 | GPa |

| Interlaminar Shear Strength | 69.8 | MPa |

| Tg Onset (DMA) | 140 | °C |

| Tg Peak (DMA) | 148 | °C |

General Properties

| Gross Weight | 2.3 | kg |

|---|---|---|

| Brand | XPREG |

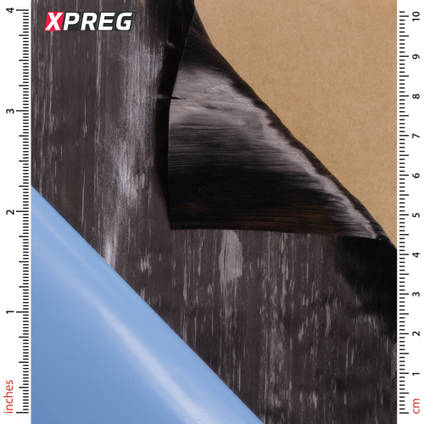

XC130 300g Unidirectional Prepreg Carbon Fibre (300mm)

- XPREG

- XC130-C12UD-300(300)-10

- No reviews

Unidirectional reinforcement using our XPREG® XC130 resin system but 100% compatible with our XC110 system. This is an uncured prepreg material and requires an oven or autoclave to cure it.

This 300gsm UD reinforcement is used to add maximum possible strength in a specific direction. It can be used on its own or combined with woven reinforcements.

This prepreg reinforcement is 0.3m (300mm) wide and sold in a choice of prepacked roll lengths.

PRODUCT VERSIONS

Roll Length

AVAILABILITY:7 in stock available for immediate shipping

50 more can built in 2-3 days

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

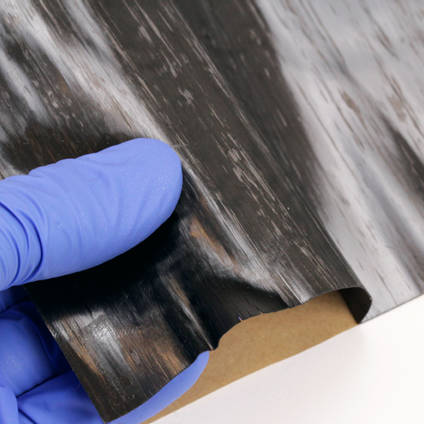

300gsm unidirectional prepreg carbon fibre made using the XPREG® XC130 resin system. This 100% unidirectional reinforcement is entirely unsupported and so has no weft fibres to disrupt the the unidirectional fibres.

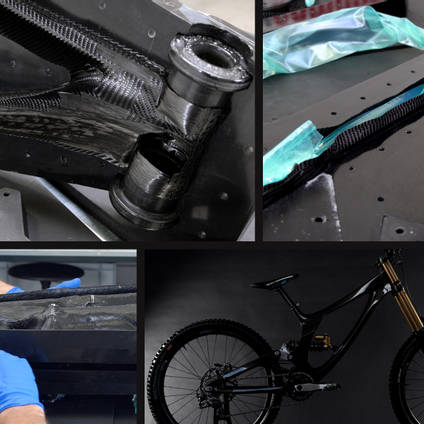

This UD prepreg can be used to add very specifically targeted (and oriented) strength to any composites component. Most typically, unidirectional reinforcement is used in conjunction with woven reinforcement to produce high performance components with strength exactly where it is needed.

This prepreg material can be used on its own or in conjunction with other XC130 prepregs (for autoclave or press curing). When cured in a press or autoclave this XC130 unidirectional prepreg can be used as any ply in the laminate, including the surface ply.

Use with XPREG® XC110 Out-of-Autoclave Prepreg

The XC130 resin system used in this prepreg is 100% compatible with the XPREG XC110 out-of-autoclave resin system and so this material can be used to add unidirectional reinforcement to laminates intended for out-of-autoclave cure.

When using XC130 prepregs (including this XC130 unidirectional carbon fibre prepreg) alongside XC110 prepregs for out-of-autoclave cure it is important to ensure that the first two plies down into the mould use the XC110 out-of-autoclave resin system. After the first two XC110 plies are down, XC130 prepregs (such as this unidirectional material) can be used without detriment to the surface finish.

How to Buy

This prepreg is supplied on a 300mm wide roll/tape and available in pre-rolled lengths of 2lm, 5lm, 10lm and the full 100lm roll.

Please choose the roll-length you require from the drop-down menu at the top of the page.

The Sample Pack Contains two 400x300mm (15.7x11.8") pieces of prepreg.

For very large or ongoing requirements please contact our sales team.

300gsm unidirectional prepreg carbon fibre made using the XPREG® XC130 resin system. This 100% unidirectional reinforcement is entirely unsupported and so has no weft fibres to disrupt the the unidirectional fibres.

This UD prepreg can be used to add very specifically targeted (and oriented) strength to any composites component. Most typically, unidirectional reinforcement is used in conjunction with woven reinforcement to produce high performance components with strength exactly where it is needed.

This prepreg material can be used on its own or in conjunction with other XC130 prepregs (for autoclave or press curing). When cured in a press or autoclave this XC130 unidirectional prepreg can be used as any ply in the laminate, including the surface ply.

Use with XPREG® XC110 Out-of-Autoclave Prepreg

The XC130 resin system used in this prepreg is 100% compatible with the XPREG XC110 out-of-autoclave resin system and so this material can be used to add unidirectional reinforcement to laminates intended for out-of-autoclave cure.

When using XC130 prepregs (including this XC130 unidirectional carbon fibre prepreg) alongside XC110 prepregs for out-of-autoclave cure it is important to ensure that the first two plies down into the mould use the XC110 out-of-autoclave resin system. After the first two XC110 plies are down, XC130 prepregs (such as this unidirectional material) can be used without detriment to the surface finish.

How to Buy

This prepreg is supplied on a 300mm wide roll/tape and available in pre-rolled lengths of 2lm, 5lm, 10lm and the full 100lm roll.

Please choose the roll-length you require from the drop-down menu at the top of the page.

The Sample Pack Contains two 400x300mm (15.7x11.8") pieces of prepreg.

For very large or ongoing requirements please contact our sales team.

Specification

Fabric Specification

| Fibre Specifics | High Strength CF | |

|---|---|---|

| Colour | Black | |

| Fibre Orientation | Unidirectional | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | Unidirectional | |

| Format | Unidirectional | |

| Fibre Type | Carbon Fibre | |

| Brand | XPREG | |

| Filament Count | 24K/50K |

Weight and Dimensions

| Width | 300 | mm |

|---|---|---|

| Consolidated Thickness | 0.3 | mm |

| Areal Weight | 300 | g/m² |

| Resin Weight | 33 | % |

Fibre Properties

| Min Cure Temp | 80 | °C |

|---|---|---|

| Max Cure Temp | 120 | °C |

| Max Service Temp | 130 | °C |

| Filament Diameter | 7 | µm |

| Out-life (at 20°C) | 30 | Days |

| Freezer-life (at -18°C) | 12 | Months |

| UV Resistance | Good |

Typical Laminate Properties

| Tensile Modulus | 55.2 | GPa |

|---|---|---|

| Tensile Strength | 645 | MPa |

| Compressive Strength | 615 | MPa |

| Flexural Strength | 882 | MPa |

| Flexural Modulus | 60.1 | GPa |

| Interlaminar Shear Strength | 69.8 | MPa |

| Tg Onset (DMA) | 140 | °C |

| Tg Peak (DMA) | 148 | °C |

General Properties

| Gross Weight | 2.3 | kg |

|---|---|---|

| Brand | XPREG |

Unfortunately we do not stock any pre-pregs with a flexible resin. The only flexible resin we supply is our EF80 Flexible Epoxy Resin which is suitable for wet lay and vacuum bagged processes.

Pre-preg needs to be stored in a freezer at -18°C in sealed bags. If stored under these conditions, the pre-preg will have a shelf life of 12 months.

Generally a minimum of 3 bar would be reasonable to get good results.

Our XC110 OOA and XC130 Autoclave Component PrePreg and XA120 material don't necessarily need to be shipped in insulated/dry ice packed boxes but is shipped direct from our freezers meaning that for at least the first 12-24hours of the delivery, it remains frozen. We even have several long-term Asia and Australian/NZ based customers who regularly purchase PrePreg from us in large quantities without issues.

The out-life of the material (the cumulative time that the PrePreg can spend out of the freezer) is at least 28 days at 20°C - as such, you should still have a minimum of 20+days of useable life left on arrival. As soon as the material arrives with you, if you put it straight into the freezer, it will preserve the remaining outlife. In most cases the 28 days is conservative too and in practice, you will get more than this.

In theory you could use either. The difference in the two cure cycles is more about ensuring a good surface finish for out of autoclave applications (using XC110 surface plies). Therefore, our recommended cure cycle for combination laminated would be the XC110 cure cycle, ensuring that the first two plies are XC110.

The fibre used is a Toray T700 which has an average fibre diameter of 7 μm.

Yes, we can export unidirectional prepreg carbon fibre to the USA but doing does require an export licence. To the USA, we can make use of an 'Open General Export Licence' (OGEL) but this does mean filling out a bit of paperwork (both on our side and yours). It's nothing too arduous, it's just about confirming that we know who we're sending it to and then it's not going to be forwarded on to any countries where it shouldn't go. However, as a result of the paperwork, we do have a minimum order value of £250 before shipping (about $330) to ensure we cover our costs.

If you place an order, we'll get in touch with the end-user declaration form which we'll need completed before we dispatch your order.

ASK YOUR OWN QUESTION

Customer Product Reviews for XC130 300g Unidirectional Prepreg Carbon Fibre (300mm)

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.