Need any help or advice?+44 (0)1782 454499

Downloads (3)

This is a chemical product. Before storage or use you must download and read the accompanying safety and technical datasheets.

| Safety Datasheet (SDS) - EN | ||

| Safety Datasheet (SDS) - NL | ||

| Technical Datasheet (TDS) |

Specification

Product Data

| Colour | Grey | |

|---|---|---|

| UV Resistance | Moderate | |

| Brand | Easy Composites | |

| Maximum Casting Thickness | 75 | mm |

| Shelf Life | 12 | Months |

Cured Mechanical Properties

| Max Service Temp | 80 | °C |

|---|---|---|

| Chemistry / Material | Epoxy | |

| Viscosity | 12500 | mPa.s |

| Hardness | 90 (Hard) | Shore D |

| Flexibility | Hard / Rigid | |

| Tensile Strength | 20 - 25 | MPa |

| Flexural Strength | 38 - 42 | MPa |

| Flexural Modulus | 6300 - 6700 | GPa |

| Elongation at Break | 1.0 - 1.5 | % |

| Tg Onset (DMA) | 80 | °C |

| Shrinkage | 0.05 | % |

| Tensile Modulus | 5000 - 5500 | MPa |

Pot Life and Cure Times

| Pot Life (Typical) | 150 | mins |

|---|---|---|

| Initial Cure Time | 12 | Hrs |

Weight and Dimensions

| Density | 1.67 | g/cm³ |

|---|

General Properties

| Gross Weight | 6 | kg |

|---|

Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

TC80 Tool Cast Epoxy Casting Resin 5.3kg

- EP-TC80-5

Hazardous

- 5/5 Average rating

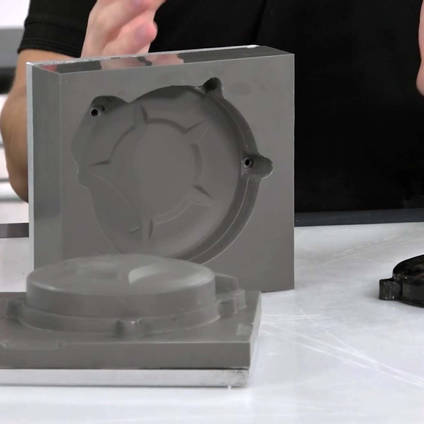

TC80 Tool Cast is an aluminium filled epoxy casting resin designed specifically for the production of high quality cast epoxy tools such as vacuum forming tools.

Sold as a kit (resin and hardener). Available to buy online in a 5.3kg kit.

AVAILABILITY:More than 10 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

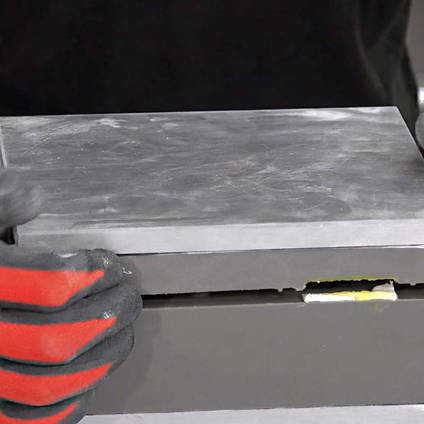

TC80 Tool Cast is an aluminium filled epoxy casting resin designed for high temperature tooling applications such as vacuum forming tools. TC80 Tool Cast cures quickly with minimal shrinkage and can be cast in relatively large volumes. The system is polishable and very hard-wearing making it ideally suited to vacuum forming and other repetitive pressing/moulding applications.

The low mixed viscosity of this two-part epoxy system ensures very accurate reproduction of even the finest surface detail.

Typical Uses

- Vacuum forming male tools

- Platen press tools

- Any cast moulds

Further Information

Key Processing Information

- Ease of Use: Suitable for professional and hobby use (follow SDS advice).

- Odour: Vac Cast is almost odourless.

- Safety Precautions: Wear gloves and goggles and work in a well ventilated area. Always read the SDS before use.

- Ambient Conditions: Can be used from 10 to 30°C although pot-life and cure time will be affected significantly. For small or thin-section castings an ambient of 20-25°C is required.

- Degassing: Not necessary. Simply mix and pour.

- Mix Ratio: Mix Resin and Hardener 100:6 by weight. Use digital scales.

- Mixing: Mix thoroughly by hand for at least 3 minutes.

- Casting Thickness: Block off sections to limit casting thickness to a maximum of 75mm<

- Pot-Life: 2-3 hours. Be sure to pour your casting(s) within this time.

- Exotherm (Over-Heating): Resin will heat-up whilst it cures. Once mixed, pour resin immediately.

- Cure Time/Demould: Demould Time 12 Hours @ 25°C

TC80 Tool Cast is an aluminium filled epoxy casting resin designed for high temperature tooling applications such as vacuum forming tools. TC80 Tool Cast cures quickly with minimal shrinkage and can be cast in relatively large volumes. The system is polishable and very hard-wearing making it ideally suited to vacuum forming and other repetitive pressing/moulding applications.

The low mixed viscosity of this two-part epoxy system ensures very accurate reproduction of even the finest surface detail.

Typical Uses

- Vacuum forming male tools

- Platen press tools

- Any cast moulds

Further Information

Key Processing Information

- Ease of Use: Suitable for professional and hobby use (follow SDS advice).

- Odour: Vac Cast is almost odourless.

- Safety Precautions: Wear gloves and goggles and work in a well ventilated area. Always read the SDS before use.

- Ambient Conditions: Can be used from 10 to 30°C although pot-life and cure time will be affected significantly. For small or thin-section castings an ambient of 20-25°C is required.

- Degassing: Not necessary. Simply mix and pour.

- Mix Ratio: Mix Resin and Hardener 100:6 by weight. Use digital scales.

- Mixing: Mix thoroughly by hand for at least 3 minutes.

- Casting Thickness: Block off sections to limit casting thickness to a maximum of 75mm<

- Pot-Life: 2-3 hours. Be sure to pour your casting(s) within this time.

- Exotherm (Over-Heating): Resin will heat-up whilst it cures. Once mixed, pour resin immediately.

- Cure Time/Demould: Demould Time 12 Hours @ 25°C

Specification

Product Data

| Colour | Grey | |

|---|---|---|

| UV Resistance | Moderate | |

| Brand | Easy Composites | |

| Maximum Casting Thickness | 75 | mm |

| Shelf Life | 12 | Months |

Cured Mechanical Properties

| Max Service Temp | 80 | °C |

|---|---|---|

| Chemistry / Material | Epoxy | |

| Viscosity | 12500 | mPa.s |

| Hardness | 90 (Hard) | Shore D |

| Flexibility | Hard / Rigid | |

| Tensile Strength | 20 - 25 | MPa |

| Flexural Strength | 38 - 42 | MPa |

| Flexural Modulus | 6300 - 6700 | GPa |

| Elongation at Break | 1.0 - 1.5 | % |

| Tg Onset (DMA) | 80 | °C |

| Shrinkage | 0.05 | % |

| Tensile Modulus | 5000 - 5500 | MPa |

Pot Life and Cure Times

| Pot Life (Typical) | 150 | mins |

|---|---|---|

| Initial Cure Time | 12 | Hrs |

Weight and Dimensions

| Density | 1.67 | g/cm³ |

|---|

General Properties

| Gross Weight | 6 | kg |

|---|

Tool Cast can be cast into tin/condensation cure silicones as well as addition/platinum cure silicones no problem.

The TC80 can be cast into a rigid mould such as a traditional GRP mould. A release agent such as Mould Release Wax or our CR1 EasyLease will work well. Be aware that traditionally using epoxy in a polyester mould can cause sticking issues so that combination should be avoided where possible, especially on newer moulds. Also take care to ensure your mould design is such that the cast resin can be easily demoulded.

It's not normally a requirement however very complicated moulds with undercuts and issues with voids may benefit from degassing and certainly wouldn't cause any problems by doing so.

New moulds made from TC80 will initially have a faithful reproduction of the surface of your pattern and so if you start with a high gloss pattern, and use an appropriate release agent, then the TC80 moulds will have exactly the same high gloss finish on them.

Where TC80 does differ from other tool surfaces however would be if you were to try to polish the TC80 to achieve a high gloss (rather than just starting with a high gloss surface straight off the pattern). The reason for this is because TC80 is heavily filled with aluminium powder; if you try to polish TC80 you will find that the epoxy and the aluminium particles abrade and polish at different rates which results in a slightly speckled surface. For this reason, polishing TC80 is possible, but - in cases where you're trying to achieve perfect surface finish - wouldn't be recommended.

If you want to 'cast' a mould, in the way that you can with TC80, but you want a highly polishable mould surface, it might be worth considering EG60 or EG160 epoxy tooling gelcoats which don't contain aluminium power and so are much more polishable. You could apply these gelcoats as the mould's surface and then back-fill (at the B-stage) with TC80.

Once fully cured it will machine quite nicely. Generally we would allow around 48 hours for the resin to cure and ensure the resin has hardened sufficiently before machining.

No, Vac Cast is an opaque solid dark grey colour. Just to avoid any confusion, Vac Cast is used for making vacuum forming tools (moulds), not for the actual vacuum forming itself. The vacuum forming could be done using a clear sheet, like Lexan.

ASK YOUR OWN QUESTION

Customer Product Reviews for TC80 Tool Cast Epoxy Casting Resin 5.3kg

I dont have a 3d printer but had some molds which was not good for high heat so i needed to make a new mould but i didnt have the original part. I pour this amazing product in to the mold! BAM! i have tool to make mold. Now the mold done and the part looks like original fits like original. i am sure this is not may be intended to do that but product is amazing. ! yes you can sand and polish.

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.