Need any help or advice?+44 (0)1782 454499

Specification

Weight and Dimensions

| Inside Diameter (ID) | 8 | mm |

|---|---|---|

| Outside Diameter (OD) | 16 | mm |

Product Data

| Max Service Temp | 60 | °C |

|---|---|---|

| Membrane Material | Polypropylene | |

| Spiral Wrap Material | Polyethylene |

General Properties

| Gross Weight | 0.141 | kg |

|---|---|---|

| Brand | AeroFilm® |

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

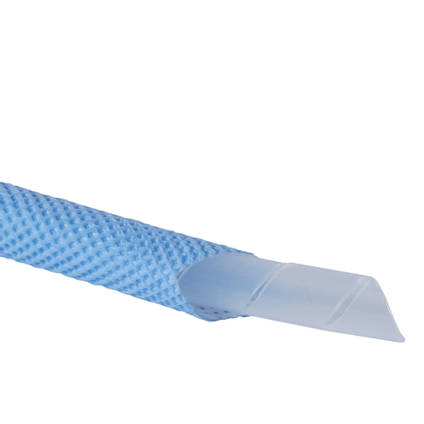

MVL Economy Microporous Vacuum Line

- AeroFilm®

- MP-MVL

- No reviews

Specifically developed for resin infusion, this low-cost, semi-permeable vacuum hose uses a microporous membrane which allows air to pass into the hose whilst allowing only minimal resin transmission. MVL Hose is a lower cost alternative to MTI® Hose for more budget conscious applications.

Sold by the linear metre.

AVAILABILITY:More than 100 availablefor immediate shipping

Trade discounts

| 0-4 | 5-9 | 10-99 | 100+ |

|---|---|---|---|

| £2.50 | £2.25 | £2.15 | £2.05 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

MVL is a low-cost alternative to the MTI Hose from DD-Compound, it is used in resin infusion to maintain vacuum along its full length throughout the process, this greatly reduces the risk of dry areas in more complex infusions, typically the hose is used for perimeter vacuum on centre or conventionally fed infusions.

Its working principle is like that of breathable waterproof clothing, in that it will allow air to pass through the membrane but effectively seals off when it is reached by the resin front, the spiral that is in the core of the hose will maintain the vacuum to any uninfused areas that would normally have become isolated in a traditional infusion stack.

The compromise of the MVL in comparison to the MTI Hose is that the membrane is slightly less effective at resisting the resin flow meaning that once saturated with resin and after prolonged vacuum some resin may pass through, in most applications this will not be problematic however for applications where the control of the resin to fibre fraction is critical the MTI hose would be a better choice. MVL is also slightly more difficult to effectively seal at the ends than MTI and generally requires the use of sealant tape and duct-tape or heat-sealing.

One potential advantage that MVL has over MTI in certain circumstances is that, due to the fact that it still remains slightly permeable after becoming wetted, it will still have the ability to evacuate small amounts of air which may be advantageous for some processes such as when there are large variations in laminate thickness.

MVL hose has an uncompressed outside diameter of ~13mm, the internal spiral hose has an O.D. of 10mm and an I.D. of 8mm.

How to Buy

MVL Hose is available to purchase by the metre or in wholesale coils of 100m. Prices shown are per meter, volume discounts are automatically calculated.

Volume Pricing

We believe we offer unbeatable prices on vac bagging consumables. To make comparisons easy, select the different pack/roll sizes from the drop-down menu above:

Further Information

Increasing Reliability

MVL Hose will increase the reliability of infusions particularly of new and complex infusions where the precise flow path has not been established, this will reduce the likelihood of scrappage and defects which could offer huge cost savings in production.

Self-Regulating

As the resin flow is almost entirely halted by the MVL hose the timing for clamping the vacuum line is no longer a critical factor in the process meaning that is does not need to be continuously monitored, Unlike the superior MTI Hose the MVL can allow a very slow leak-past of resin so we would not suggest leaving this under permanent vacuum but instead clamp the lines like you would in a traditional infusion, albeit in a much less critical time window. Although we would always recommend the use of a catch-pot as a precautionary measure, MVL Hose will generally render a catch-pot redundant so it would be possible to run a direct connection to the vacuum pump.

Typical Use

Typically, the MVL Hose is laid around the perimeter of the moulding wherever vacuum needs to be maintained. The ends of the MVL Hose seal easily and effectively using conventional vacuum bagging sealant tape in combination with duct-tape, alternatively the ends can also be sealed using hotmelt adhesive. The vacuum hose connection can be made by feeding the vacuum hose into the MTI Hose and sealing in the same manner, this vacuum hose would typically breach the bag through the sealant tape on the flange. Although the hose will still allow for full vacuum to be achieved it will slow the initial pull down time so take care to ensure to bag generally conforms well to the mould before closing to reduce the pull-down time.

Leak Fixing

It is a common misconception that microporous products eliminate the need to ensure that the vacuum bag is perfectly sealed, the (incorrect) theory being that as the vacuum can be maintained through the cure that the bag can be held down even with a leak, although it is true that a microporous vacuum line might be able to help to hold a bag and material roughly in place in the event of a leak it will not do this effectively enough for the part not to be severely compromised. Compared with MTI hose the MVL does remain slightly more porous to air once wetted, allowing air to pass quite freely, whilst this may prove advantageous for component geometries that could lead to trapped air in the flow front it should not be considered a substitute for a perfectly sealed bag.

Related Products

MTI Hose - Microporous Vacuum Line

MTI Hose is the premium version of the MVL Hose; MTI Hose in the most part serves the same role as the MVL hose however the membrane used is superior and will completely prevent resin ingress over prolonged periods and end-sealing is easier and can be effectively achieved using only sealant tape.

MTI Valve - Resin Inlet Regulator

The MTI Valve can be used in conjunction with microporous vacuum lines/strips, its purpose is to create a regulated back pressure on the resin inlet which ensures that the part does not become over-saturated with resin and in turn increases the consistency of infused parts.

MVS Microporous Vacuum Strip

MVS is used where vacuum is needed in the centre of the part rather than the perimeter, being flat form it does not cause a 'print-through', this is available in 2 widths; 100 and 300mm.

Trade discounts

| 0-4 | 5-9 | 10-99 | 100+ |

|---|---|---|---|

| £2.50 | £2.25 | £2.15 | £2.05 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

MVL is a low-cost alternative to the MTI Hose from DD-Compound, it is used in resin infusion to maintain vacuum along its full length throughout the process, this greatly reduces the risk of dry areas in more complex infusions, typically the hose is used for perimeter vacuum on centre or conventionally fed infusions.

Its working principle is like that of breathable waterproof clothing, in that it will allow air to pass through the membrane but effectively seals off when it is reached by the resin front, the spiral that is in the core of the hose will maintain the vacuum to any uninfused areas that would normally have become isolated in a traditional infusion stack.

The compromise of the MVL in comparison to the MTI Hose is that the membrane is slightly less effective at resisting the resin flow meaning that once saturated with resin and after prolonged vacuum some resin may pass through, in most applications this will not be problematic however for applications where the control of the resin to fibre fraction is critical the MTI hose would be a better choice. MVL is also slightly more difficult to effectively seal at the ends than MTI and generally requires the use of sealant tape and duct-tape or heat-sealing.

One potential advantage that MVL has over MTI in certain circumstances is that, due to the fact that it still remains slightly permeable after becoming wetted, it will still have the ability to evacuate small amounts of air which may be advantageous for some processes such as when there are large variations in laminate thickness.

MVL hose has an uncompressed outside diameter of ~13mm, the internal spiral hose has an O.D. of 10mm and an I.D. of 8mm.

How to Buy

MVL Hose is available to purchase by the metre or in wholesale coils of 100m. Prices shown are per meter, volume discounts are automatically calculated.

Volume Pricing

We believe we offer unbeatable prices on vac bagging consumables. To make comparisons easy, select the different pack/roll sizes from the drop-down menu above:

Further Information

Increasing Reliability

MVL Hose will increase the reliability of infusions particularly of new and complex infusions where the precise flow path has not been established, this will reduce the likelihood of scrappage and defects which could offer huge cost savings in production.

Self-Regulating

As the resin flow is almost entirely halted by the MVL hose the timing for clamping the vacuum line is no longer a critical factor in the process meaning that is does not need to be continuously monitored, Unlike the superior MTI Hose the MVL can allow a very slow leak-past of resin so we would not suggest leaving this under permanent vacuum but instead clamp the lines like you would in a traditional infusion, albeit in a much less critical time window. Although we would always recommend the use of a catch-pot as a precautionary measure, MVL Hose will generally render a catch-pot redundant so it would be possible to run a direct connection to the vacuum pump.

Typical Use

Typically, the MVL Hose is laid around the perimeter of the moulding wherever vacuum needs to be maintained. The ends of the MVL Hose seal easily and effectively using conventional vacuum bagging sealant tape in combination with duct-tape, alternatively the ends can also be sealed using hotmelt adhesive. The vacuum hose connection can be made by feeding the vacuum hose into the MTI Hose and sealing in the same manner, this vacuum hose would typically breach the bag through the sealant tape on the flange. Although the hose will still allow for full vacuum to be achieved it will slow the initial pull down time so take care to ensure to bag generally conforms well to the mould before closing to reduce the pull-down time.

Leak Fixing

It is a common misconception that microporous products eliminate the need to ensure that the vacuum bag is perfectly sealed, the (incorrect) theory being that as the vacuum can be maintained through the cure that the bag can be held down even with a leak, although it is true that a microporous vacuum line might be able to help to hold a bag and material roughly in place in the event of a leak it will not do this effectively enough for the part not to be severely compromised. Compared with MTI hose the MVL does remain slightly more porous to air once wetted, allowing air to pass quite freely, whilst this may prove advantageous for component geometries that could lead to trapped air in the flow front it should not be considered a substitute for a perfectly sealed bag.

Related Products

MTI Hose - Microporous Vacuum Line

MTI Hose is the premium version of the MVL Hose; MTI Hose in the most part serves the same role as the MVL hose however the membrane used is superior and will completely prevent resin ingress over prolonged periods and end-sealing is easier and can be effectively achieved using only sealant tape.

MTI Valve - Resin Inlet Regulator

The MTI Valve can be used in conjunction with microporous vacuum lines/strips, its purpose is to create a regulated back pressure on the resin inlet which ensures that the part does not become over-saturated with resin and in turn increases the consistency of infused parts.

MVS Microporous Vacuum Strip

MVS is used where vacuum is needed in the centre of the part rather than the perimeter, being flat form it does not cause a 'print-through', this is available in 2 widths; 100 and 300mm.

Specification

Weight and Dimensions

| Inside Diameter (ID) | 8 | mm |

|---|---|---|

| Outside Diameter (OD) | 16 | mm |

Product Data

| Max Service Temp | 60 | °C |

|---|---|---|

| Membrane Material | Polypropylene | |

| Spiral Wrap Material | Polyethylene |

General Properties

| Gross Weight | 0.141 | kg |

|---|---|---|

| Brand | AeroFilm® |

ASK YOUR OWN QUESTION

Customer Product Reviews for MVL Economy Microporous Vacuum Line

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.