Need any help or advice?+44 (0)1782 454499

Specification

Weight and Dimensions

| Width | 1000 | mm |

|---|---|---|

| Areal Weight | 200 | g/m² |

| Consolidated Thickness | 0.59 | mm |

Fabric Specification

| Fibre Specifics | FlaxDry BL200 | |

|---|---|---|

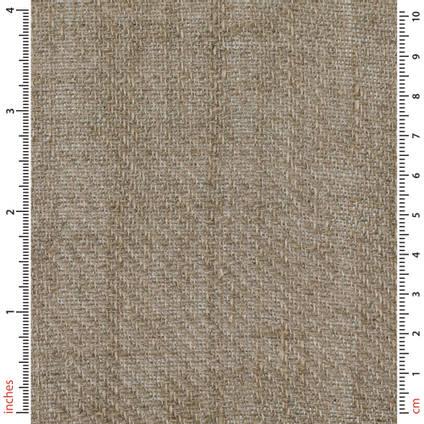

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric |

Product Data

| Colour | Brown | |

|---|---|---|

| Fibre Type | Flax Fibre | |

| Brand | EcoTechnilin |

Mechanical Properties

| Ends | 10.2 | cm |

|---|---|---|

| Picks | 10.1 | cm |

General Properties

| Gross Weight | 0.3 | kg |

|---|---|---|

| Brand | Eco-Technilin |

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

When packaged, this product is over 1m in length. A small additional handling charge will apply when shipping to some countries and regions. When applicable, this handling charge will be included in the automatic shipping calculation shown on the basket page.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

200g 2x2 Twill Flax Fibre Cloth (1000mm)

- Eco-Technilin

- FF-22-200-100

- No reviews

FLAXDRY-BL200 flax fibre from Eco-Technilin is an environmentally friendly and sustainable alternative to traditional composite reinforcements such as glass fibre.

As well as its environmental credentials, flax fibre has an attractive natural aesthetic and excellent vibration damping properties. It is suitable for most laminating processes including hand-layup, vacuum bagging and resin infusion.

This woven cloth is 1m wide and sold by the linear metre.

AVAILABILITY:73 in stock available for immediate shipping

Trade discounts

| 0-4 | 5-29 | 30+ |

|---|---|---|

| £18.20 | £14.15 | £10.95 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

This 200gsm flax cloth is the lightest of our woven flax cloths. Its fine weave and smooth texture is well suited to use as a surface ply.

About Flax Fibre

Flax fibre is environmentally friendly and sustainable alternative to traditional composite reinforcements such as glass fibre.

Although flax fibre offers lower overall strength and stiffness compared to reinforcements such as glass fibre, it does offer particular advantages in vibration damping and sound absorption, along with adequate mechanical properties and a great natural aesthetic to complement its environmental credentials.

How to Process

Flax fibre can be processed in a similar way to most dry composite reinforcements including glass or carbon fibre reinforcement and is suitable for use with a wide variety of resins such as epoxy, vinylester and polyester resin, including more sustainable or environmentally friendly synthetic and bio-based systems. Flax reinforcement can be used on its own or in conjunction with other types of reinforcement, including glass or carbon, to achieve the desired properties or appearance.

Dry flax fibre can be laminated using a range processes including hand layup, vacuum bagged hand layup, resin transfer moulding (RTM) and resin infusion.

It is particularly well suited to resin infusion with the fibre’s structure allowing good resin flow through the laminate. The vacuum consolidation results in a high fibre to resin ratio and the vacuum infusion process produces void free laminates with an excellent visual appearance.

Typical Uses

Flax reinforcement is most typically used in applications with a focus on environmental sustainability, in particular products like canoes, kayaks, paddle boards, furniture and leisure products designed for environmentally conscious consumers. When used without a coloured paint or gelcoat, flax fibre has a low-key, natural appearance, perfectly in keeping with homes, workspaces and lifestyles of this growing market.

Flax fibre is also used in mass-market applications for its vibration absorption and sound deadening properties such as parcel shelves and door liners for the automotive sector.

- Canoes, kayaks, and paddleboards

- Skis, snowboards, skateboards

- Dinghies, yachts

- Furniture, architectural mouldings, and panels

- Parcel shelves, door liners

Bio Resins

To support our range of natural fibres, Easy Composites has sourced a range of bio epoxy resins which use plant derived content from sustainable sources to lower environmental impact without compromising on performance. They are an ideal match for use with these flax fibres. We have our LB2 bio derived epoxy laminating resin which you can find here: LB2 Epoxy Laminating Bio Resin and our IB2 Infusion grade epoxy resin here: IB2 Epoxy Infusion Bio Resin.

How to Buy

This 200g flax fibre cloth is 1m (39") wide and the fabric is sold by the linear metre. Simply enter the qty according to the number of linear metres you want to buy; the fabric will be supplied in one continuous length.

The unit price shown is for 1 linear metre but volume discounts automatically apply for larger quantities of fabric.

Please note: When ordering quantities of less than 5m, the flax will be supplied carefully folded and bagged. Flax is a flexible and resilient material and is not damaged by folding in this way but if you want to ensure the material is supplied on a roll, please order a minimum of 5m.

Storage

Flax fibre should be stored in a cool dry place away from direct sunlight. Flax fibre can absorb moisture from the atmosphere so drying may be required before use, especially if exposed to excessive humidity.

About Eco-Technilin

With 20 years of experience, France-based Eco-Technilin is the European leader in the technical use of natural fibres. Easy Composites are proud to be the exclusive UK distributor for Eco-Technilin and support them in their goal to make environmentally friendly technical materials as affordable and accessible as possible.

Trade discounts

| 0-4 | 5-29 | 30+ |

|---|---|---|

| £18.20 | £14.15 | £10.95 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

This 200gsm flax cloth is the lightest of our woven flax cloths. Its fine weave and smooth texture is well suited to use as a surface ply.

About Flax Fibre

Flax fibre is environmentally friendly and sustainable alternative to traditional composite reinforcements such as glass fibre.

Although flax fibre offers lower overall strength and stiffness compared to reinforcements such as glass fibre, it does offer particular advantages in vibration damping and sound absorption, along with adequate mechanical properties and a great natural aesthetic to complement its environmental credentials.

How to Process

Flax fibre can be processed in a similar way to most dry composite reinforcements including glass or carbon fibre reinforcement and is suitable for use with a wide variety of resins such as epoxy, vinylester and polyester resin, including more sustainable or environmentally friendly synthetic and bio-based systems. Flax reinforcement can be used on its own or in conjunction with other types of reinforcement, including glass or carbon, to achieve the desired properties or appearance.

Dry flax fibre can be laminated using a range processes including hand layup, vacuum bagged hand layup, resin transfer moulding (RTM) and resin infusion.

It is particularly well suited to resin infusion with the fibre’s structure allowing good resin flow through the laminate. The vacuum consolidation results in a high fibre to resin ratio and the vacuum infusion process produces void free laminates with an excellent visual appearance.

Typical Uses

Flax reinforcement is most typically used in applications with a focus on environmental sustainability, in particular products like canoes, kayaks, paddle boards, furniture and leisure products designed for environmentally conscious consumers. When used without a coloured paint or gelcoat, flax fibre has a low-key, natural appearance, perfectly in keeping with homes, workspaces and lifestyles of this growing market.

Flax fibre is also used in mass-market applications for its vibration absorption and sound deadening properties such as parcel shelves and door liners for the automotive sector.

- Canoes, kayaks, and paddleboards

- Skis, snowboards, skateboards

- Dinghies, yachts

- Furniture, architectural mouldings, and panels

- Parcel shelves, door liners

Bio Resins

To support our range of natural fibres, Easy Composites has sourced a range of bio epoxy resins which use plant derived content from sustainable sources to lower environmental impact without compromising on performance. They are an ideal match for use with these flax fibres. We have our LB2 bio derived epoxy laminating resin which you can find here: LB2 Epoxy Laminating Bio Resin and our IB2 Infusion grade epoxy resin here: IB2 Epoxy Infusion Bio Resin.

How to Buy

This 200g flax fibre cloth is 1m (39") wide and the fabric is sold by the linear metre. Simply enter the qty according to the number of linear metres you want to buy; the fabric will be supplied in one continuous length.

The unit price shown is for 1 linear metre but volume discounts automatically apply for larger quantities of fabric.

Please note: When ordering quantities of less than 5m, the flax will be supplied carefully folded and bagged. Flax is a flexible and resilient material and is not damaged by folding in this way but if you want to ensure the material is supplied on a roll, please order a minimum of 5m.

Storage

Flax fibre should be stored in a cool dry place away from direct sunlight. Flax fibre can absorb moisture from the atmosphere so drying may be required before use, especially if exposed to excessive humidity.

About Eco-Technilin

With 20 years of experience, France-based Eco-Technilin is the European leader in the technical use of natural fibres. Easy Composites are proud to be the exclusive UK distributor for Eco-Technilin and support them in their goal to make environmentally friendly technical materials as affordable and accessible as possible.

Specification

Weight and Dimensions

| Width | 1000 | mm |

|---|---|---|

| Areal Weight | 200 | g/m² |

| Consolidated Thickness | 0.59 | mm |

Fabric Specification

| Fibre Specifics | FlaxDry BL200 | |

|---|---|---|

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric |

Product Data

| Colour | Brown | |

|---|---|---|

| Fibre Type | Flax Fibre | |

| Brand | EcoTechnilin |

Mechanical Properties

| Ends | 10.2 | cm |

|---|---|---|

| Picks | 10.1 | cm |

General Properties

| Gross Weight | 0.3 | kg |

|---|---|---|

| Brand | Eco-Technilin |

That depends on the resin system used. The limiting factor will be the HDT of the resin system. A typical epoxy resin may be capable of 80°C with an oven post cure.

ASK YOUR OWN QUESTION

Customer Product Reviews for 200g 2x2 Twill Flax Fibre Cloth (1000mm)

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

When packaged, this product is over 1m in length. A small additional handling charge will apply when shipping to some countries and regions. When applicable, this handling charge will be included in the automatic shipping calculation shown on the basket page.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.