Need any help or advice?+44 (0)1782 454499

Specification

Weight and Dimensions

| Thickness | 6 | mm |

|---|---|---|

| Length | 480 | mm |

| Width | 480 | mm |

Product Data

| Colour | Black | |

|---|---|---|

| Appearance | 2x2 Twill (Glossy) | |

| Type | Single Sided | |

| Resin Matrix | Epoxy |

Fabric Specification

| Fibre Orientation | 0, 90 |

|---|

Mechanical Properties

| Tg Onset (DMA) | 70 | °C |

|---|

Cured Mechanical Properties

| Tensile Modulus at 0/90° | 6610 | MPa |

|---|---|---|

| Tensile Modulus at 45° | 2060 | MPa |

| Tensile Strength at 0/90° | 71.4 | MPa |

| Tensile Strength at 45° | 36.7 | MPa |

| Elongation at Break at 0/90° | 2.64 | % |

| Elongation at Break at 45° | 24.2 | % |

| Young's Modulus at 0/90 | 9.52 | GPa |

| Compressive Strength | 1.33 | MPa |

| Compressive Modulus | 72.5 | GPa |

| Core Sheer Strength | 1.09 | MPa |

| Core Sheer Modulus | 27.75 | MPa |

| Core Thermal Conductivity at RT | 0.033 | W/mK |

| Maximum Water Absorption | 37.5 | g/m2 |

General Properties

| Gross Weight | 0.62 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Foam Cored Carbon Fibre Panel

- FCP-RI-6-0230

- No reviews

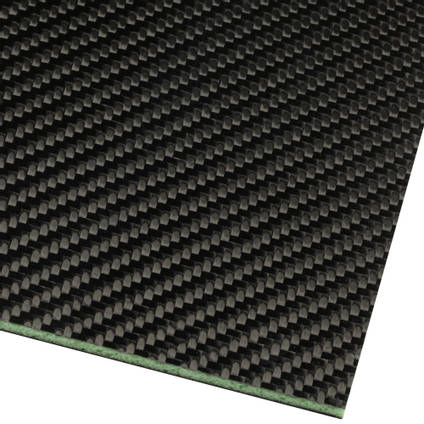

Manufactured by Easy Composites in the UK. Premium quality foam cored carbon fibre panel manufactured using 100% high-strength carbon fibre reinforcement sandwiched either side of a low density structural core material. These panels have a smooth, glossy, cosmetic quality carbon fibre finish on one side and a smooth, satin finished carbon fibre finish on the reverse.

These high performance are designed to provide the maximum stiffness for the minimum weight and are ideal for a range of applications including motorsport, marine, shopfitting, exhibitions, automation, medical, scientific and more.

Available in 4mm, 6mm and 11mm thicknesses in a range of sheet sizes up to 2sqm.

PRODUCT VERSIONS

Sheet Size

Thickness

AVAILABILITY:13 in stock available for immediate shipping

Trade discounts

| 0-4 | 5-9 | 10-19 | 20+ |

|---|---|---|---|

| £49.75 | £47.25 | £44.75 | £42.25 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Manufactured at Easy Composites in the UK using advanced technology, our High Strength Carbon Fibre Foam Core Panel achieves the ultimate combination of strength, light weight and stunning appearance making the panel ideal for a wide range of uses from structural engineering applications through to exhibition systems and architectural use.

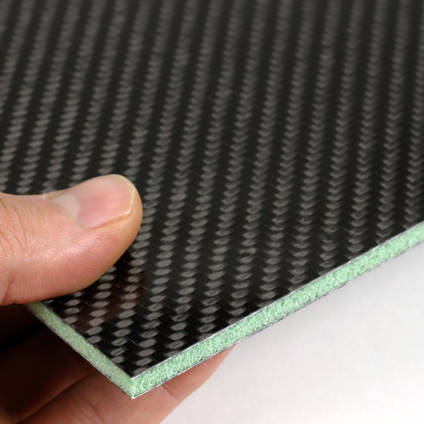

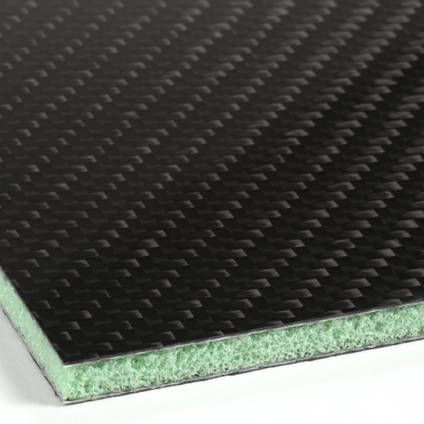

This specially developed foam-cored carbon fibre panel is available in 4mm, 6mm and 11mm thicknesses and is manufactured using a combination of genuine high-strength 2/2 twill 3k carbon fibre combined with a layer of biaxial carbon (4mm panels) or woven E-glass (6mm and 11mm panels) either side of a lightweight closed-cell PVC foam core to create a lightweight panel with excellent deflection strength.

For maximum strength-to-weight ratio the sheets are manufactured without any gelcoat or surface coating but our propriety resin technology ensures a glossy, pin-hole free 'class-A' surface on the cosmetic face.

Resin matrix is epoxy throughout with a high temperature post-cure for maximum mechanical performance.

Appearance

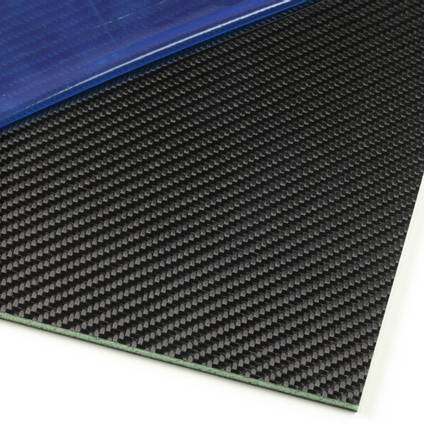

The cosmetic 'A' side of the panel has a high gloss carbon fibre finish, protected by a removable blue protective film.

The reverse side is a smooth, satin carbon fibre finish but it is not intended to be a cosmetic face and as such some visual imperfections or light scratches from pressing, handling and cutting are to be expected. Note: we often also add a blue film to the reverse side of the sheet, just to minimise handling scratches, but this does not indicate that the reverse ('B' side) is intended to be a cosmetic finish.

Typical Uses

Available in sheet sizes up to 2000mm x 980mm and in thicknesses from 4mm to 11mm, these high strength carbon fibre panels are suited to use a wide range of projects:

- Lightweight Structural/Engineering Projects

- Vehicle Panelling / Undertrays

- Carbon Fibre Splitters

- Marine Panelling

- Exhibition Systems / Displays

- Architectural Use

Advantages

Utilising a foam core allows us to make a panel of maximum stiffness for the minimum possible weight. Conventional ‘solid’ carbon fibre sheets, made without a core material, are significantly heavier for the same deflection strength. The dimensional tolerance on length and width is typically + - 2.5mm.

Typical Uses

Cutting, Shaping & Finishing

As with all carbon fibre and composites (like fibreglass, carbon Kevlar etc.) good results can be achieved for cutting, shaping and finishing this sheet using regular workshop tools like hacksaws, jigsaws and wet-and-dry. Specialist tools can, however, make lighter work of the job and produce better results.

We recommend Perma-Grit tools for the cutting and shaping of our carbon fibre sheet.

Trade discounts

| 0-4 | 5-9 | 10-19 | 20+ |

|---|---|---|---|

| £49.75 | £47.25 | £44.75 | £42.25 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Manufactured at Easy Composites in the UK using advanced technology, our High Strength Carbon Fibre Foam Core Panel achieves the ultimate combination of strength, light weight and stunning appearance making the panel ideal for a wide range of uses from structural engineering applications through to exhibition systems and architectural use.

This specially developed foam-cored carbon fibre panel is available in 4mm, 6mm and 11mm thicknesses and is manufactured using a combination of genuine high-strength 2/2 twill 3k carbon fibre combined with a layer of biaxial carbon (4mm panels) or woven E-glass (6mm and 11mm panels) either side of a lightweight closed-cell PVC foam core to create a lightweight panel with excellent deflection strength.

For maximum strength-to-weight ratio the sheets are manufactured without any gelcoat or surface coating but our propriety resin technology ensures a glossy, pin-hole free 'class-A' surface on the cosmetic face.

Resin matrix is epoxy throughout with a high temperature post-cure for maximum mechanical performance.

Appearance

The cosmetic 'A' side of the panel has a high gloss carbon fibre finish, protected by a removable blue protective film.

The reverse side is a smooth, satin carbon fibre finish but it is not intended to be a cosmetic face and as such some visual imperfections or light scratches from pressing, handling and cutting are to be expected. Note: we often also add a blue film to the reverse side of the sheet, just to minimise handling scratches, but this does not indicate that the reverse ('B' side) is intended to be a cosmetic finish.

Typical Uses

Available in sheet sizes up to 2000mm x 980mm and in thicknesses from 4mm to 11mm, these high strength carbon fibre panels are suited to use a wide range of projects:

- Lightweight Structural/Engineering Projects

- Vehicle Panelling / Undertrays

- Carbon Fibre Splitters

- Marine Panelling

- Exhibition Systems / Displays

- Architectural Use

Advantages

Utilising a foam core allows us to make a panel of maximum stiffness for the minimum possible weight. Conventional ‘solid’ carbon fibre sheets, made without a core material, are significantly heavier for the same deflection strength. The dimensional tolerance on length and width is typically + - 2.5mm.

Typical Uses

Cutting, Shaping & Finishing

As with all carbon fibre and composites (like fibreglass, carbon Kevlar etc.) good results can be achieved for cutting, shaping and finishing this sheet using regular workshop tools like hacksaws, jigsaws and wet-and-dry. Specialist tools can, however, make lighter work of the job and produce better results.

We recommend Perma-Grit tools for the cutting and shaping of our carbon fibre sheet.

Specification

Weight and Dimensions

| Thickness | 6 | mm |

|---|---|---|

| Length | 480 | mm |

| Width | 480 | mm |

Product Data

| Colour | Black | |

|---|---|---|

| Appearance | 2x2 Twill (Glossy) | |

| Type | Single Sided | |

| Resin Matrix | Epoxy |

Fabric Specification

| Fibre Orientation | 0, 90 |

|---|

Mechanical Properties

| Tg Onset (DMA) | 70 | °C |

|---|

Cured Mechanical Properties

| Tensile Modulus at 0/90° | 6610 | MPa |

|---|---|---|

| Tensile Modulus at 45° | 2060 | MPa |

| Tensile Strength at 0/90° | 71.4 | MPa |

| Tensile Strength at 45° | 36.7 | MPa |

| Elongation at Break at 0/90° | 2.64 | % |

| Elongation at Break at 45° | 24.2 | % |

| Young's Modulus at 0/90 | 9.52 | GPa |

| Compressive Strength | 1.33 | MPa |

| Compressive Modulus | 72.5 | GPa |

| Core Sheer Strength | 1.09 | MPa |

| Core Sheer Modulus | 27.75 | MPa |

| Core Thermal Conductivity at RT | 0.033 | W/mK |

| Maximum Water Absorption | 37.5 | g/m2 |

General Properties

| Gross Weight | 0.62 | kg |

|---|

Whether or not cut edges would benefit from sealing really comes down to the application and environment where the sheet will be used, specifically, we're really talking about prolonged or permanent exposure to liquids like water, chemicals, oil etc. In an application where the cut edge of the sheet is going to be regularly or permanently exposed to liquids then it would be beneficial to seal the edge to prevent water ingress which, over enough time, can travel down the fibres and cause delamination.

Based on the above, if edge sealing is deemed advantageous then it's best done using some epoxy resin which should be mixed (according to its accompanying instructions) and either be brushed or smeared on the cut edge, or the cut edge dipped in it. Although it's by no means critical, a particularly suitable resin would be our XCR Epoxy Coating Resin.

It's not possible to give an exact weight because it would depend on many things (how the sheet is supported, what the span in, how the weight it loaded, whether the sheet is a 'free span' (i.e. not bonded/fixed) or bonded or fixed (so you get a 'drum skin' effect). That said, you could be confident that a sheet slid over a hole such that the sheet is supported on all sides would support the weight of an average person quite easily.

The foam used in this sheet is our EasyCell 75, for which the datasheet is readily available here: EasyCell 75. The properties for the carbon fibre and glass used in the sheet we don't currently have data for but we are having mechanical property testing done on the finished foam core panel for which the data should be available soon.

The majority of the tests were done to DIN EN ISO 527-4. The flexural properties were done to DIN EN ISO 14125.

Hi David, as you suggest, the key when fitting to a cored panel like this is not crushing the core with force that's too localised. This can be done using machined fittings, like a top-hat section, or it can be done by removing the foam and filling the cavity with solid material (usually epoxy resin). I'm afraid we don't have fitting bushes because there's too much variation in what dimensions (bush diameter, thread size, flange diameter) that may be required, if required, these would usually be machined to spec.

Removing and solid filling the core can be very effective though and is easily done. You drill through the inside skin, then remove any remaining core material (you can even go a bit wider than the diameter of the drill hole) and then fill the cavity with a mix of epoxy resin. This creates an uncrushable core section that's bonded to the inside of the outer skin (and potentially to some of the inside of the inner skin too). Depending on what you're fixing the panel to, you could use a pan washer to spread the load onto the inside skin, bond on a spreader plate or leave it as it is (especially if you've been able to remove core underneath the inside skin too).

What’s the intended final use of the panel?... If it's something along the lines of a splitter then you can add rubber trim around the leading edge, this is easy to do, will leave a neat finish and protect the vulnerable foam of the panel.

If you really want to extend the same woven carbon fibre finish around the edge of the panel then this would be incredibly difficult and pretty much the only way to do it would be to make a moulded part, i.e. start with a mould and then laminate a new part where the carbon fabric followed the contour of the moulded lip. A more realistic ‘half-way’ option would be to fill the edge with a carbon filler; this can look very neat, matches the colour of the carbon fabric, and will provide strength and protection for the exposed edge. To do this, you would remove about 3mm of the foam core, all the way around, and then use a product like our Black Epoxy Repair Filler to fill the 3mm gap. Once it’s cured, you can flat and polish it to a high quality finish.

Each skin on both the 6mm and 11mm panels, is approximately 0.5mm thick

The foam used in these panels is our EasyCell 75 Closed cell PVC foam in either 5mm or 10mm thickness.

The maximum working temperature for this sheet is 70C.

The Foam core panel is fractionally stiffer than the 3mm resin infused sheet. It is also significantly lighter in weight and easier to cut. However, the 3mm resin infused sheet, being solid laminate, is much tougher and impact resistant than the foam cored panel.

Water jet cutting will cut the foam core panel easily and quickly. As with most composites, adjustment of the water jet settings may be necessary for the cut to remain clean and not chip or delaminate the edge of the sheet.

For example, I want to route out one skin and bend the other to create a 90deg bend. Also because the main loading will be shear I intend to cut out my parts at 45deg to the panel edges.

No, not around a 90 degree bend. The problem would be the carbon sheet on the outer skin which would not be able to be bent around a 90 degree (or even 45 degree) corner without having a significant radius. If the bend was around a tight radius then the sheet is likely to fracture.

ASK YOUR OWN QUESTION

Customer Product Reviews for Foam Cored Carbon Fibre Panel

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.